Fill Your Welder Performance Qualification Record Form

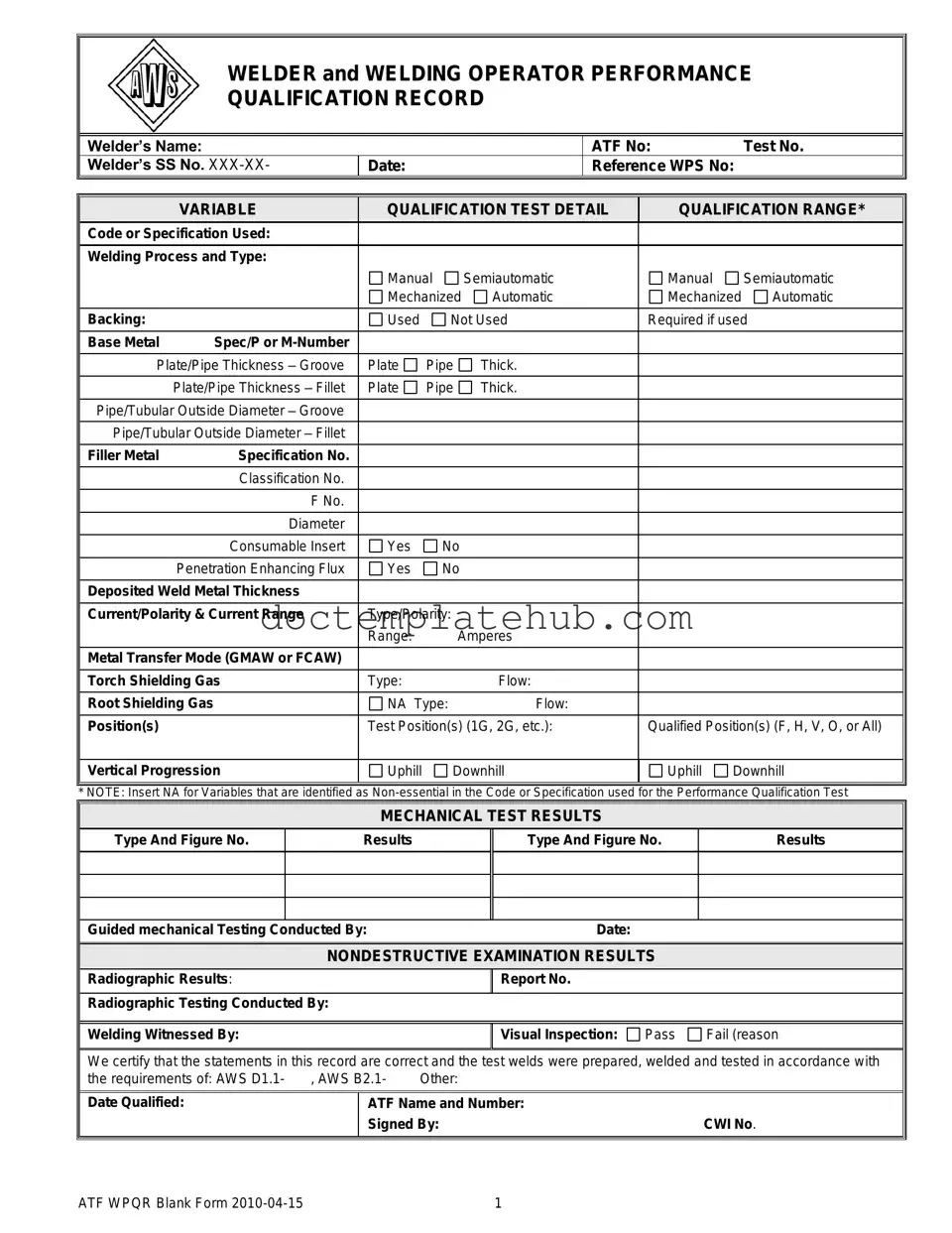

The Welder Performance Qualification Record form is a vital document in the welding industry, serving as a comprehensive record of a welder's skills and qualifications. This form captures essential information about the welder, including their name, identification numbers, and the specific tests they have completed. It outlines the reference Welding Procedure Specification (WPS) used during testing, ensuring that all welding practices meet industry standards. The form details various qualification parameters, such as the type of welding processes employed—ranging from manual to automatic—and the materials involved, including base metals and filler materials. Additionally, it includes crucial test results from both mechanical and non-destructive examinations, providing a clear picture of the welder's capabilities. The form also specifies the positions in which the welder is qualified to work and the conditions under which the tests were conducted. Ultimately, this record not only verifies a welder's competence but also plays a significant role in maintaining safety and quality standards within the welding profession.

Similar forms

The Welder Performance Qualification Record (WPQR) is closely related to the Welding Procedure Specification (WPS). Both documents are essential in the welding process. The WPS outlines the specific parameters and techniques that a welder must follow to ensure quality and safety. While the WPQR focuses on the individual welder's qualifications, the WPS provides the framework within which those qualifications are applied. Together, they ensure that welding meets industry standards and is performed correctly.

The California Vehicle Purchase Agreement form is a crucial document that outlines the terms and conditions between a buyer and a seller when purchasing a vehicle in California. This agreement ensures both parties are clear on the details of the transaction, from the price to any warranties or conditions. Understanding this form can help make your vehicle purchase smoother and more secure. For more information, you can refer to the documentonline.org/blank-california-vehicle-purchase-agreement.

Another important document is the Procedure Qualification Record (PQR). The PQR serves as evidence that a specific welding procedure can produce welds that meet the required standards. While the WPQR verifies the skills of the welder, the PQR confirms that the welding process itself is sound. Both documents work hand in hand, as a qualified welder must operate under a qualified procedure to ensure high-quality welds.

The Certificate of Qualification is also similar to the WPQR. This document certifies that a welder has successfully completed a qualification test. It often includes information about the tests taken and the results achieved. Like the WPQR, it serves as proof of a welder's capabilities. However, the Certificate of Qualification may not include the detailed test results that the WPQR provides, making it less comprehensive.

Additionally, the Welding Inspection Report (WIR) bears similarities to the WPQR. The WIR documents the results of inspections performed on welds. It may include visual inspections, non-destructive testing results, and any defects found. While the WPQR focuses on the welder's qualifications, the WIR emphasizes the quality of the welds produced. Both documents are crucial for maintaining quality assurance in welding projects.

The Non-Destructive Testing (NDT) Report is another related document. This report details the findings from tests that assess the integrity of welds without causing damage. It is essential for ensuring that welds meet safety and quality standards. Like the WPQR, the NDT Report is vital for compliance with industry regulations. Both documents contribute to the overall reliability of welding processes.

The Welder Certification is yet another document that aligns with the WPQR. This certification confirms that a welder has met specific training and testing requirements. It often accompanies the WPQR and serves as a formal acknowledgment of a welder's skills. While the WPQR provides a detailed account of the welder's performance, the certification is a more straightforward validation of their qualifications.

The Welding Log is also similar to the WPQR in that it records the details of welding activities. This log typically includes information on the date, location, and type of welds performed. It helps track a welder's experience over time. Although it does not provide the same level of qualification detail as the WPQR, it serves as a useful tool for monitoring a welder's ongoing work and development.

Lastly, the Quality Control Plan (QCP) can be compared to the WPQR. The QCP outlines the procedures and standards for ensuring quality in welding operations. It includes details on inspections, testing, and documentation processes. While the WPQR focuses on individual welder qualifications, the QCP encompasses the broader quality assurance measures that an organization must follow to maintain high standards in welding practices.

Other PDF Templates

Can You Spare a Dollar Fundraiser Sheet - It only takes a dollar to show your commitment!

When creating a Durable Power of Attorney in New York, it is essential to utilize reliable resources to ensure accuracy and legality. For detailed guidance and templates, you can visit smarttemplates.net, which provides comprehensive tools to facilitate this important task.

Pest Control Service Agreement Template - This contract serves as a written record of the services agreed upon and the expectations set for both parties.

Verification Forms - This form should be treated with care and respect for all parties involved.

More About Welder Performance Qualification Record

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record (WPQR) form serves as a vital document that verifies a welder's skills and qualifications. It provides a comprehensive record of the tests a welder has completed, showcasing their ability to perform specific welding tasks according to industry standards. This form is essential for employers who need to ensure that their welders meet the necessary qualifications before they begin work on projects that require certified welding. It acts as proof that the welder has been tested and has met the criteria set forth by relevant codes and specifications.

What information is required on the WPQR form?

The WPQR form requires several key pieces of information. This includes the welder's name, identification numbers, and the date of the qualification test. Additionally, it details the reference Welding Procedure Specification (WPS) number, the welding process used, and specifics about the base metal and filler metal. The form also captures test results, including mechanical testing and non-destructive examination results, ensuring a thorough record of the welder's performance. Each section is designed to provide a complete overview of the welder's capabilities and the conditions under which they were tested.

How long is the qualification valid, and when does it need to be renewed?

The validity of a welder's qualification can vary based on the specific codes or standards being followed, as well as the policies of the employer. Generally, qualifications are valid for a period of six months to three years, depending on the type of welding performed and the materials used. If a welder has not performed a specific type of welding within that timeframe, they may need to retake the qualification test. Employers often keep track of their welders' qualifications to ensure compliance with industry standards and safety regulations.

What types of tests are included in the qualification process?

The qualification process typically includes both destructive and non-destructive testing methods. Mechanical tests, such as tensile tests and bend tests, assess the strength and ductility of the welds. Non-destructive examinations, like radiographic or visual inspections, evaluate the integrity of the weld without damaging it. These tests ensure that the welder not only has the technical skills to perform the welds but also understands the importance of producing high-quality work that meets safety and performance standards.

Who is responsible for completing and signing the WPQR form?

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, attention to detail is crucial. Here’s a list of things to do and avoid, ensuring that the process is smooth and compliant.

- Do double-check the welder’s name and identification numbers for accuracy.

- Do ensure that the date of the test is clearly marked.

- Do specify the correct welding process and type to reflect the actual test performed.

- Do include all relevant details regarding the base metal specifications.

- Do indicate whether backing was used, as this can affect the qualification.

- Don’t leave any sections blank; fill in all required fields to avoid delays.

- Don’t forget to document the results of mechanical tests and non-destructive examinations.

- Don’t use abbreviations or shorthand that may confuse the reader.

- Don’t sign the form without verifying that all information is correct and complete.

By following these guidelines, you can help ensure that the Welder Performance Qualification Record is filled out accurately and efficiently. This not only supports the welder’s qualifications but also upholds the standards required in the industry.

Welder Performance Qualification Record - Usage Steps

Completing the Welder Performance Qualification Record form is a critical step in documenting a welder's skills and qualifications. The following steps outline how to accurately fill out this form to ensure all necessary information is captured correctly.

- Enter the welder’s name in the designated space.

- Fill in the ATF number and the test number.

- Provide the welder’s Social Security number.

- Record the date of the qualification test.

- Input the reference WPS number.

- Specify the code or specification used for the qualification.

- Select the welding process and type (manual, semiautomatic, mechanized, or automatic).

- Indicate whether backing was used or not.

- Fill in the base metal specification and P or M-number.

- Document the plate or pipe thickness for groove and fillet welds.

- Record the outside diameter for groove and fillet pipe/tubular welds.

- Enter the filler metal specification number and classification number.

- Indicate the filler metal diameter and whether a consumable insert was used.

- Specify if penetration enhancing flux was used.

- Document the deposited weld metal thickness.

- Fill in the current/polarity and current range, including amperes.

- State the metal transfer mode (GMAW or FCAW).

- Specify the torch shielding gas type and flow rate.

- Indicate the root shielding gas type and flow rate, if applicable.

- List the test position(s) and qualified position(s).

- Document the vertical progression (uphill or downhill).

- Record the results of any mechanical tests conducted.

- Fill in the details of the guided mechanical testing, including who conducted it and the date.

- Provide the radiographic results and report number.

- Indicate who conducted the radiographic testing.

- Document who witnessed the welding process.

- Conduct a visual inspection and note whether it passed or failed, including reasons for failure if applicable.

- Certify that the information is correct and that the tests were conducted per the relevant requirements.

- Enter the date qualified.

- Fill in the ATF name and number.

- Sign the form and include the CWI number.